Cov khoom

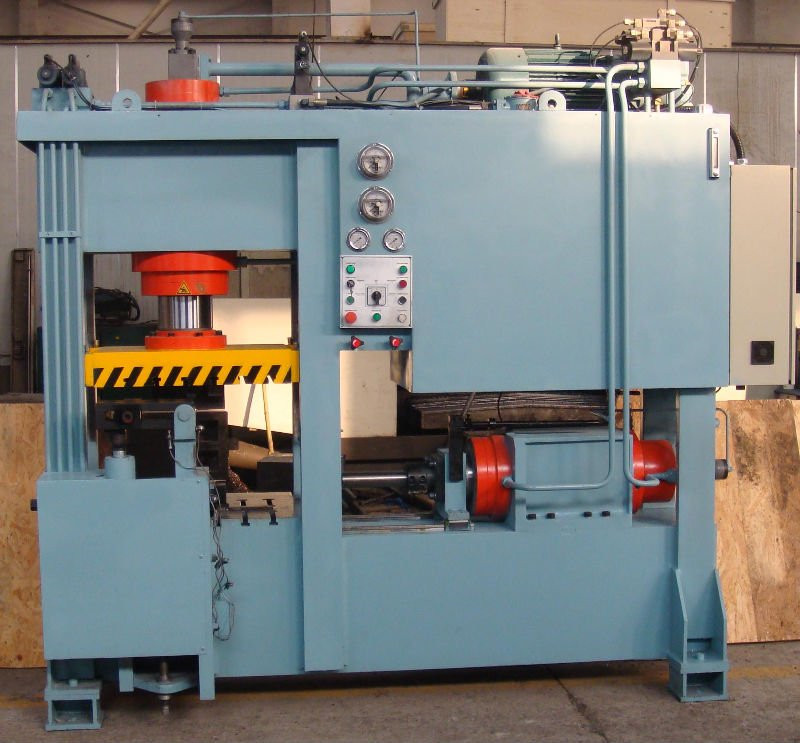

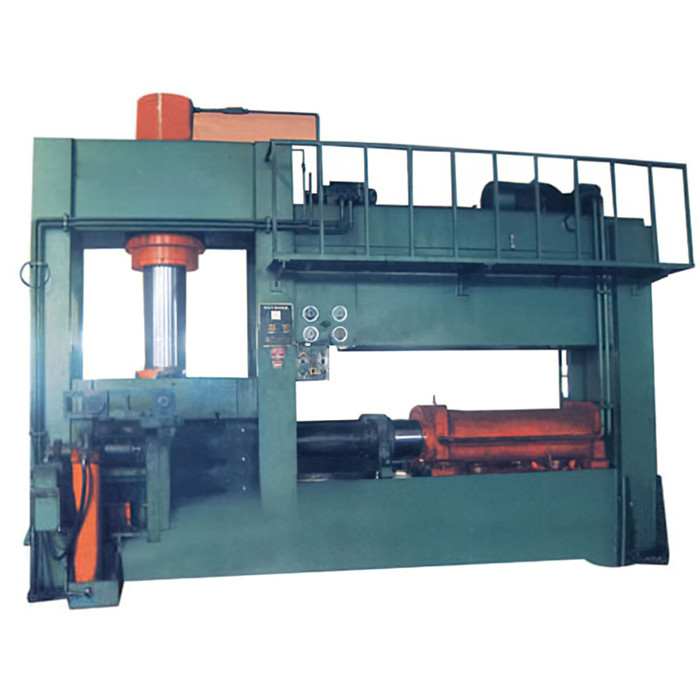

txias forming luj tshib tshuab

Khoom npe: Cov Khoom Uas Zoo Txias Ua Lub Luj Tshib Tshuab

Qhov xwm txheej: Tshiab

Hom: txias sib sau tshuab Ebow, hydraulic txias sib sau

Cov khoom siv yeeb nkab: CS SS Alloy Stainless Hlau

Daim Ntawv Thov: Hluav Taws Xob Hluav Taws Xob

Lub zog: 380v

Lub zog: 30KW

Qhov Loj (L * W * H): 5800X3200X4700

Luj: 2500kg

Kev paub meej

| HOM PARAMETER | ZTW-219 ~ 325 |

| PRODUCTION CAPACITY (mm) | Ø 219-325 |

| Thickness (mm) | 3 ~ 20 |

| Ua kua dej siab (MPa) | 25 |

| LOCKING NOMINAL Pressure (KN) | 6300 ib |

| LOCKING MAX TRAVELING DISTANCE (mm) | 1360 |

| PUSHING NOMINAL Pressure (KN) | 3 150 |

| PUSHING MAX TRAVELING DISTANCE (mm) | 1330 ib |

Cold Forming Luj Tshuab yog tsim los rau kev tsim khoom 90 & 45 degree R = 1.0D & R = 1.5D lub luj tshib nrog txoj kab uas hla ntawm 1/2 "mus rau 32" ntawm stainless hlau, carbon steel, alloy steel thiab qee yam ntawm cov hlau tsis zoo.Ua raws li cov qauv ntawm ASME B16.9, ASMEB16.11, GB12459, JIS, DIN thiab GOST, cov khoom siv wildly siv nyob rau hauv kev lag luam ntawm Petrochemical, Roj thiab Gas pipeline, Fais fab nroj tsuag, metallurgy, thiab zaub mov thiab lwm yam.

Lub ntsiab nta

Ob hom qauv tsim: kev sib xyaw ua ke thiab plaub kab ke.Ua kev kho cua sov rau lub tshuab lub cev kom tso cov kev ntxhov siab welding.

* Lub proportional logical circuit hydraulic system khiav nrog servo lub cev muaj zog ua rau lub tshuab txuag hluav taws xob, tsis muaj suab nrov, ua haujlwm ruaj khov thiab lub neej ntev.

* Daim ntawv thov ntawm PLC nrog lub vijtsam kov pom tau tias khaws cia txias qhov tsis sib xws (ua nrawm, siab thiab lub sijhawm voj voog thiab lwm yam) hauv qhov nruab nrab PLC system los ntawm kov npo.Tib neeg-lub computer interface ua haujlwm yooj yim heev.

* Peb hom kev ua haujlwm suav nrog phau ntawv, semi-automatic thiab tsis siv neeg, uas tuaj yeem hloov pauv tau yooj yim.

* Electricaland hydraulic system siv cov khoom zoo tshaj plaws uas tau los ntawm lub teb chaws Yelemees, Nyiv, Ltalis thiab Taiwan kom paub meej tias kev ua haujlwm zoo tshaj plaws.

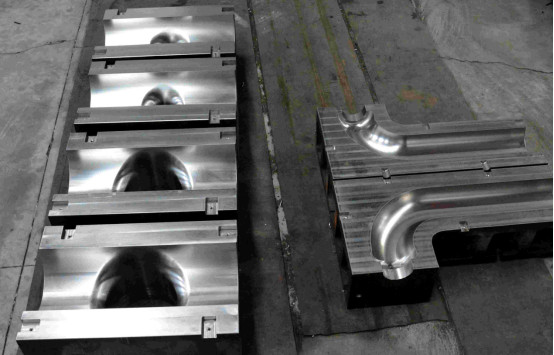

* Tshwj xeeb tsim pwm qhov chaw cov cuab yeej siv tau yooj yim dua pwm sib dhos.Nws txuag ntau lub sijhawm thiab nqi zog ntawm cov pwm thiab mandrels.

* Lub luj tshib tuaj yeem tsim nyob rau hauv ib zaug, cov duab calibration yuav tsis xav tau.Haum rau kev tsim khoom loj nrog kev ua haujlwm siab tshaj plaws.

* Lub tshuab ua lub luj tshib hydro-forming muaj lub laj kab tiv thaiv thiab kev cuam tshuam kev nyab xeeb los xyuas kom muaj kev nyab xeeb ntawm kev ua haujlwm.Lub tshuab tuaj yeem raug saib xyuas kom ntseeg tau tias muaj kev nyab xeeb ua haujlwm.

* Cov qauv tshwj xeeb ntawm lub taub hau thawb thiab thawb rods yog tsim los ntawm kev sib txawv ntawm qhov ntau thiab tsawg thiab phab ntsa thicknesses, uas ua kom muaj qhov tsim nyog piv thiab siab precision.

* Roj cua txias system ua kom lub sijhawm ntev ua haujlwm txhua hnub.